Still roadworthy, a conversation with Paul Nieuwenhuis

I was born outside Eindhoven and used to cycle to school every day past the DAF factory. So, I’ve been a car guy from a very early age. In the 1980s, I worked for a management consultancy specialising in the car industry, which was spun off from the University of East Anglia.

DAF Factory. Suyk, Koen / Anefo | Nationaal Archief

It was clear that there was an increasing awareness of environmental pressures within the car industry, perhaps much more than in other industries. Much of that came from California, which had the first emissions control regulations aimed explicitly at cars starting in the late 1950s.

The Californian regulation

Historically, the area where they built the city of Los Angeles is full of tar oil. Even the Chumash Indians knew it as a place with bad air. It’s got the sea on one side and the mountains all the way around. It is a basin that holds bad air. There, they built a massive city, stuck it full of cars and trucks, and created an enormous port full of ships. It was going to be one of the first places in the world to hit this problem.

People first started to notice differences in air quality from the 1940s onwards. They noticed that when they moved to L.A., the sky was blue, but with time it turned brown.

Why was that? They started to look into it and suggested for the first time that cars were the problem. They made changes before the federal government did. Even today, they are allowed to legislate separately from federal legislation.

Smog blankets Los Angeles in 1958. Photograph: AP

This means California regulations will continue to be created by the California Air Resources Board in Sacramento. Several other states started to follow this in the 1990s. The federal government decided that States could follow federal or California’s legislation but nothing else. About 20 or 30 states follow California regulations. They’ve become quite significant.

In the early 1990s, when I was with Cardiff University Business School, we had a centre for automotive industry research. I was recruited into that as one of the researchers. Because I had already been studying the car industry from an environmental perspective in my consultancy days, I brought that environmental perspective with me. I also brought my first book, which was published in 1992, The Green Car Guide. I wrote that with two colleagues from my consultancy days (n.a. Peter Cope, Janet Armstrong).

Very few studies like ours were available. But it was clear that the California Air Resources Board was critical to it all, at least for emissions and air quality legislation. Much of our work was going to Sacramento, talking to the California Air Resources Board, and then coming back to Europe and letting everyone know what would happen.

One thing we found, which was very difficult to sell to our academic bosses, is that the car industry was aware of the negative impact of emissions from a very early stage. Even though they may not have acted accordingly, they knew what was coming. They had people in place who could deal with these technologies. (how did they know it - examples?)

We then said, listen, the impact of the car is not just tailpipe emissions; it’s much broader. That’s also covered in that little book, The Green Car Guide, where we explore other things we must consider.

Economies of scale

During the 1990s, I started to pursue those different strands of activity because it was pretty clear that tailpipe emissions were controlled: they were subject to a legislative trajectory, but the other things were not.

One of the areas was product durability. I was one of the first to emphasise that the habit of throwing away a car after 15 years was foolish. Some people picked up my research in that area at the time, including the New Economics Foundation here in the U.K., who have done similar work on white goods. We organised a few workshops together where they focused on white goods and consumer goods, and I focused on cars.

One of the problems of the car industry is overproduction. This is also why cars are thrown away after 15 years because cars are pushed into the system at the front, making them prematurely obsolete, and therefore people get rid of them.

We then started to understand why the production volumes were what they were. And at that stage, my colleague Peter Wells and I started to look into where those economies of scale came from. We were both within the economic section of the business school at the time, and economists seemed to think economies of scale were economies of scale.

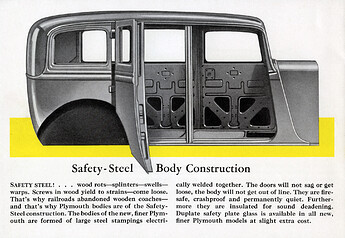

But once we started digging, we realised that’s not the case. It depends on the technology that the car industry uses that forces the economies of scale: the all-steel body.

Cars consist of basically a welded steel box. That is where the high investment is.

Archived by: Steve Shook

This was quite a novel work. We spent a lot of time on the history of mass production by going into stuffy libraries in the U.S. and looking through contemporary sources from 1910 to 1915. Edward Budd developed the all-steel welded body around 1912-14 when Ford created the moving production line.

Edward Budd. Public Domain

We also discovered Ford did not mass-produce cars. The Model T was essentially a running chassis. It was a car without a body. If you go back historically, people saw the car as a mechanical device; you’d take it to your coachbuilder, and they would put a body on it. That’s how it was thought of. Nowadays, if you go into a car factory, all you see are bits of steel being stamped and welded into bodies. Then the body is painted. After that, some people come around to put seats in it, wheels on it, and engines in it. But that was a key innovation.

1925 Ford Model T Touring Car

We then discovered this transition from the way Ford made cars and production using the way cars are made today. That was the crucial step. It was Budd who was vital in that. And that rolls out in the twenties and thirties and beyond.

But the problem is that such a capital-intensive technology forces economies of scale. As a result, a modern car plant’s break-even point for a mass-produced model is between 180,000 and 200,000 a year. They lose money when they fall below that unless they are a specialist producer. Their only option is to produce at that level and then sell.

We published our findings in the 1990s in the public domain. We know where the problem is. If you get rid of that technology, then you can go for lower economies of scale and not be forced to produce in those high volumes. They can then build cars that can last longer and perhaps create a different business model whereby you make the car, then you keep it in the market, maintain it in the market, and just keep it going. That’s not even looking at the circular economy side but looking at the vehicle in use.

Alternative business models

Fortunately, in the U.K., the country is full of low-volume car makers. We started to work with some of them, including Lotus and Morgan. We did the rounds here and in Germany and Italy, where low-volume car productions also exist.

I was on a government advisory committee together with Charles Morgan (N.A. the managing director of the Morgan Motor Company, a UK car manufacturer). I got to know him quite well. We helped him explain to his financial backers how his business model was completely different from that of the Fords and General Motors.

We got to understand how you can make cars in lower volumes, and we published quite an influential paper, not in academic circles but in industry circles in 2000. We proposed a new alternative business model based on low-volume manufacturers, a fracturing localised to its market, and combined it with a sales and maintenance model. It’s called micro factory retail, where small industrial units assemble cars, and customers buy straight from those assembly facilities. They can specify the vehicle to their needs, and local suppliers can feed into it.

If demand for new cars declines, the company can deal with maintenance, repair, upgrading, and recycling. This was picked up by several people around the world, including local motors. They use a crowdfunding model whereby people can chip in and essentially design their own car using a centralised piece of basic software they can help configure.

Locally, we were approached by a guy called Hugo Powers. He has since set up the company Riversimple, based in Wales. Although it is a small business, they’re swamped. He picked up this idea because he could see that the ideas he had already been forming would fit quite nicely with this business model. He got some backing from members of the Percy family and others. He’s developed a small hydrogen fuel cell car. He’s building a fleet of 50 cars that will be placed with people in the local area. His business model is based on a kind of leasing, a product service system. You lease the car, and then the company takes them back and reconfigures them for the next customer. They do all the repair and maintenance that’s needed.

One of his arguments was that when you look at the fuel cell cars that the industry has, they are mainly large American cars. But what if you can get small off-the-shelf fuel cells for next to nothing. The entire car is much cheaper by configuring a very lightweight small car around that. That’s what he’s done. It’s a very lightweight little car, and it does everything you need it to do.

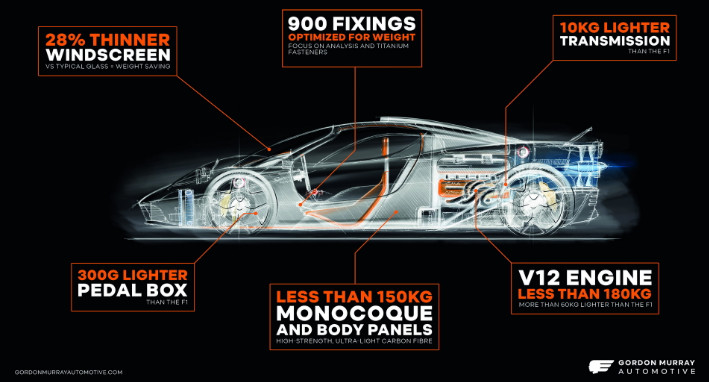

Gordon Murray designed the first carbon fibre monocoque Formula One car and a road car, the McLaren F1, which is supposed to be the best supercar ever made. Now I’ve never driven one. I can’t afford one. But he has enormous prestige in the car industry.

Murray decided around 2000 he wanted to venture into environmental car design. He came to us and picked up on the micro-factory retailing idea as well. His model is that he develops concepts, including the manufacturing concept. The product can then be placed around the world. You would have a network of factories.

That’s also how we envisage the micro-factory retailing concept. Not everybody needs to do the design. The basic design is something that’s modularised, and the factory is modularised, but then you can configure it locally for local tastes and allow local suppliers to come in.

–

With the transition to electric vehicles, vehicle technology will become more straightforward than an internal combustion engine. That is an advantage. And you don’t need emissions control, which is where a lot of the engine management computer work comes in.

But, back to durability, humanity has been doing product durability for thousands of years. We didn’t have a throwaway society, but it has developed in the last 100 years. If you look at what Henry Ford said (I quote him frequently, in spite of his political stance) when he sold the Model T, “the man who buys one never to have to buy another.”

He envisaged that if you bought your Model C, you would keep it for life. A whole aftermarket industry, especially in the U.S., supplied bits for it. If your Model T was too basic (and they were very basic), you could add all sorts of things. Many of those were designed by ordinary drivers, ordinary citizens, and small-scale inventors.

In the 1920s and thirties, the car industry was gradually professionalised, whereby the car industry decided “We don’t want all these people tinkering with our products. We want to control everything.” I describe this to some extent in my 2014 book.

This has now taken an extreme form with Tesla. Tesla has a total control system to the extent that if you start fiddling around with a Tesla, a voice will come out of the car and say, “What are you doing to our cars?”

We have long advocated this sort of hands-on approach for various reasons. But product durability is not just a technological issue, and it’s also a psychological issue. You must build a relationship with the product to look after it and to make it last a long time. I’ve done some papers on the classic car movement. I’m a classic car owner myself. My classic car is it’s a Dutch DAF. It’s a 55 coupe, of which very few are in the U.K. I’m also the chairman of the DAF Owners Club in the U.K.

Photo by: Harry_NL

With classic cars, you get people who essentially take an old banger and just keep it going, spend money on it, and lavish a lot of love and attention just to keep it going. My DAF 55 was designed for a working life of ten years, and it’s 50 years old now and still roadworthy. It passed its periodic test a few weeks ago.

The classical movement could form a model for a future, more durable car. But that would mean that the manufacturer needs to give up some control frequency. That is going to be a real challenge. However, all over the world, freedom-to-tinker legislation is popping up for various sectors where consumers will be given an inherent right to do things to the products once they’ve bought them.

Now, this is where a slight problem comes in because the environmental movement often advocates a product surface system approach whereby the end user doesn’t own the product, but the manufacturer or a management company manages it. That, of course, means that you would have less ownership of the product and less of that bond. Within an ownership model, it’s easier to build that bond. This is something that needs to be resolved in some way.

The only problem when thinking of the circular economy is controlling that waste stream. If you have a very intensively used product, you still have a fast waste stream, and you need to work out how to deal with that. Whereas with a personal ownership model, your waste stream could be delayed. For example, if a car lasts 30 years instead of 15, that greatly hinders the waste stream.

In the 1970s, Polish researchers studied how long a car could last by using different materials on behalf of the German Democratic Republic to assess. They deny all knowledge of it, but I have a copy and referenced it in many of my works. The research reckons a car can easily last 25 to 30 years with minor improvements.

–

The used cars flows

We did a study about 20 years ago about the flow of used cars around the world. We went to the U.S. but found flows from there to the Middle East - mainly Lincoln Town cars and similar ones.

The most interesting flow we found was from Japan. In Japan, they have a rigorous periodic testing regime. Essentially, after five years, you must completely rebuild your braking system. Cars are expensive to repair in Japan but cheap to buy. Many people decide they’ll buy a new car after five or seven years, and the old cars are shipped somewhere.

The biggest market for those is New Zealand. New Zealand imports between 120 and 150,000 used Japanese cars every year. And again, most ordinary New Zealanders drive those used Japanese cars and keep them going.

Some flows go from there into East Africa and the Caribbean. A similar flow goes from South Korea into Russia via Vladivostok. You could see fishing boats from Russia with several cars piled on the deck.

Screengrab cars on deck

The reason for these strict rules is purely to protect domestic car manufacturers. That’s the main drive.

This is one of the reasons why the German rules, for example, are quite rigorous. And why in Germany you can’t modify cars. All sorts of restrictions specify what kind of alloy wheels you can fit to your cars in Germany, whereas here, for example, you can stick anything on your ride. That sort of legislation is driven by the car manufacturers under the guise of safety, but, IMO, it has very little to do with safety.

Car manufacturing is the world’s largest manufacturing industry still. Of course, it’s bigger in some countries than in others, especially in countries like Japan and Germany. But also, the U.S. has quite a strong car lobby and a very strong car union. The United Auto Workers in the U.S. can put a lot of pressure on the government, for example, to stop car makers from producing in Mexico. And then metal in Germany, which is also the union for the car industry, not just for the metal industry, is Europe’s most powerful union. Unions and car makers in tandem determine a lot.

–

Peter and I first came across the circular economy in the 1990s. One thing that struck us - because this coincided with our work on looking at mass production alternatives is that the circular economy model assumed a static technology situation.

Of course, the steel from which most cars are made is very recyclable. But if you build a circular economy system around that, it assumes cars are made of steel. When we were doing this work, alternative materials were entering the industry.

For example, Renault Espace has essentially galvanised steel framework onto which there are plastic panels. It’s a hybrid technology. Audi’s Jaguar also makes largely aluminium cars. A lot of companies now make aluminium cars. Aluminium is also recyclable, so you need to find demand for steel and aluminium.

Then you get technologies like the BMW i3. We spent some time with BMW looking at how the i3 is made. It’s a little BMW electric car. It’s built on an aluminum platform and has a carbon fibre superstructure. Carbon fibre is a bugger to recycle. You can only grind it down and use the powder you get as a filler for other products. On the other hand, a structure like that of the BMW i3 should last 40 or 50 years without too many problems. So you get all those trade-offs.

BMW i3

In this period, we’re in the middle of transitioning from internal combustion engines to electric motors. You can melt internal combustion engines down and turn them into new castings either out of cast iron or aluminium, but do you necessarily have a demand for whatever it produces?

That’s why another thing we flagged: how do you understand your circular economy? I have the circularity within one product, within one product, one in one industry, within one sector, within a locality, and within a region. How does your circularity work? Because, at the moment, many of the recyclers from various industries end up in other kinds of products, like old tires in playground rubble.

From talking to the people who promote the circular economy concept, the loops are much closer. And that is something I have yet to see fully discussed or resolved.

There are three points we mentioned specifically. The first point is that close-loop homes on reuse and recycling. We need to look into the most important: to reduce.

Then, the other one is creating a static system where material innovations are discouraged because they complicate the loop. Lithium, for example, is a classic with lithium batteries. But if you change the battery technology to another one - and there are many other technologies in the pipeline - what do you do with all the waste lithium from the older batteries? From the current crop of cars? How do you accommodate that? These things can all be done, but you must be prepared. This refers to the waste hierarchy.

And then the final point, the third point, is what area within your loop operates in? A closed loop needs to be more specific as to whether the loop should be closed within a single product type, e.g. mobile phones, computers, or cars. Or within one sector? e.g., construction or within one economy. And if so, is that a local, regional or national economy? So those are our main three areas of concern about the closed-loop economy.

When we first looked at it in 1990, it still needed to be addressed. And I’ve been to some conferences in recent years, as have some of my co-authors on this book, and we’ve yet to see people discuss that in any detail. Currently, the concept is still too theoretical, and too conceptual.

Yet, now is when we need to get to the nuts and bolts of how we will do this. The data is coming through, and the information is coming from what sort of material flows will be produced in the future and how they differ from existing material flows. But these things need to be addressed within the circular economy community.