The TREASURE Project Spring School, held in Paris from April 24th to 26th and organized by NextMove, brought together a diverse group of stakeholders, including project partners and industry experts. This 3-day event facilitated the exchange of knowledge and fostered collaboration among project partners. Partners presented their ongoing work within the TREASURE project and external guests presented their work and projects within the automotive and circular economy spheres. This exchange of expertise provided valuable insights into the broader landscape of sustainable practices within the industry.

For this event, Edgeryders created an ethnographic exercise for the participants of the Spring school and presented the results of the exercise.

Day 1

The first day of the event was held at Mama’s Shelter Hotel, welcoming around 40-50 participants. During this day diverse TREASURE project members presented their work and findings related to the project. There were also guest speakers from Valeo and FROVIA.

(photo by: Bojan)

It was opened by the host Laurent Vautier giving a short introduction, presenting the objectives of this event and the planning of the Spring School, followed by a guest speaker from PFA - a French association bringing together the automotive industry in France to define and execute the industry’s strategy and its interests. The presentation presented their roadmap for the circular economy, focusing on regulatory frameworks, contribution to ADEME studies and ways of fostering of circular economy.

The event continued with presentations of TREASURE project partners and opened with a presentation by Paolo Rosa from POLIMI about the TREASURE project, objectives, goals and partners.

(photo by Bojan)

This presentation was followed by presentations from TXT presenting the web platform during which Edgeryder’s GraphRyder and visualisations were mentioned, SUPSI presenting “Greta”, POLIMI presenting their work on COBOT (a robot used to dismantle PCBs) and research work on critical raw materials, UNI presenting joint work on a standardisation document - CEN Workshop and it concluded with my presentation on ethnographic method in our research, Paris spring school exercise and its findings.

Bojan giving a presentation with findings

Normally, this part of the event should be followed with a Q&A session, but due to tight timing, we had to move to the guest presentations from Valeo and FROVIA.

Valeo in partnership with Stellantis is focusing on building cleaner, safer and smarter mobility. Their mission is to extend the lifetime of a final assembled product as long as possible through 4Rs (robust design, repair, remanufacturing, recycle).

Forvia is an interesting company focusing on carbon neutrality and trying to achieve carbon-zero production by 2045. Their main focus is on cockpit transformation design, using only recyclable materials.

All the presentations from Day 1 can be found here

Day 2

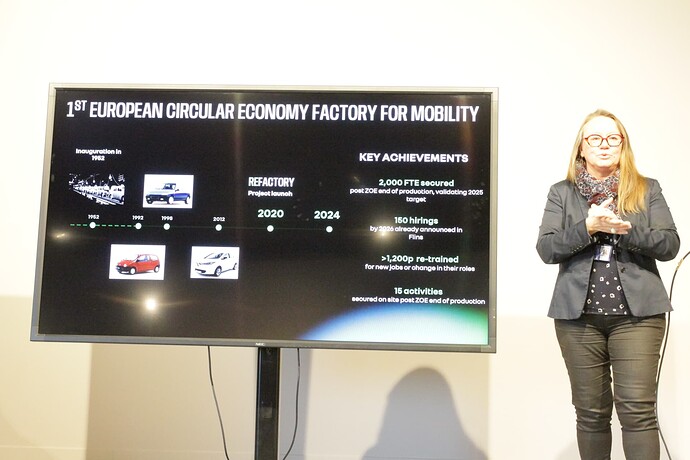

On Day 2 we had a very interesting trip to the Renault factory, visiting ReFactory facilities, and getting presented with their work followed by a NextMove collaborative training exercise on linear and circular economy.

It started with a Renault Refactory presentation (The Future Is Neutral) followed by a short discussion and Q&A. Renault Refactory is a project started in 2020 with 4 main components: Re-trofit, Re-battery, Re-cycle and Re-start. Its main focus is on the usage stage of the car’s lifecycle aiming to remanufacture the parts and to extend the vehicle’s life.

(photo by: JVD)

After this short presentation, we were divided into two groups and started our visit to Refactory facilities. We visited Re-manufactury and Re-trofit.

In the Re-manufactury facility, we were presented with the history of the activities and main tasks.

In the process, the equipment gets first disassembled and then cleaned, followed by quality checks, assembly (if needed) and packaging.

Motor before and after renovation

(photo by: JVD)

Customers gain 30-40% for the second-hand remanufactured parts, getting a 1y warranty. A lot of quality checks compared to the brand-new equipment. Good for carbon footprint.

Re-trofit facility for used cars has a very straightforward line of tasks. The cars are examined, fixed and tested. After that, they are going to painting and esthetic quality control. The final step is taking photos and uploading them directly to the cloud where suppliers and partners can immediately see the car.

Re-trofit facility

Renault is also refurbishing and fixing the robots (ABB, FANUC, KUKA) they use in their facilities. The robots are first dismantled and cleaned. Each robot is then fixed and tested so it can be reused again.

Testing cage of ABB robot

In the afternoon, we had a training workshop organised by NextMove. Due to confidentiality, we are not allowed to share the game or findings of the game. Nevertheless, this game aimed to understand the differences between the linear economy process and the circular economy process and what steps and actions we can undertake to participate in the circular economy efficiently as an everyday user.

This exercise was followed with a final meeting of the day, discussing new things learned, sharing impressions and asking final questions.

Group photo of all the participants of the Day 2

(photo by: JVD)

Day 3

On Day 3 we had a final day of the event for project members and sister projects. The event was held at CCFA (Committee of French Automobile Manufacturers). During this day, Polimi presented the other projects and initiatives they are currently working on.

(photo by: Bojan)

Furthermore, sister projects like Bosch, OFFIS, CIRC-UITS, Contintental, Ecotron, Free4Lib and EECONE presented their work followed by a short Q&A session and discussion. We moved on a short discussion of future potential collaboration, followed by a closing of the meeting and the whole Spring School event.

(photo by: JVD)